ITER Organization has developed a specific cryogenic pump to pump gases out of the ITER torus. Gases are absorbed on activated charcoal cooled to a temperature of about 4.5K built into the pump casing. The assembly is completed by an 800mm diameter inlet valve controlled by an actuator and used to separate the pump from the torus.

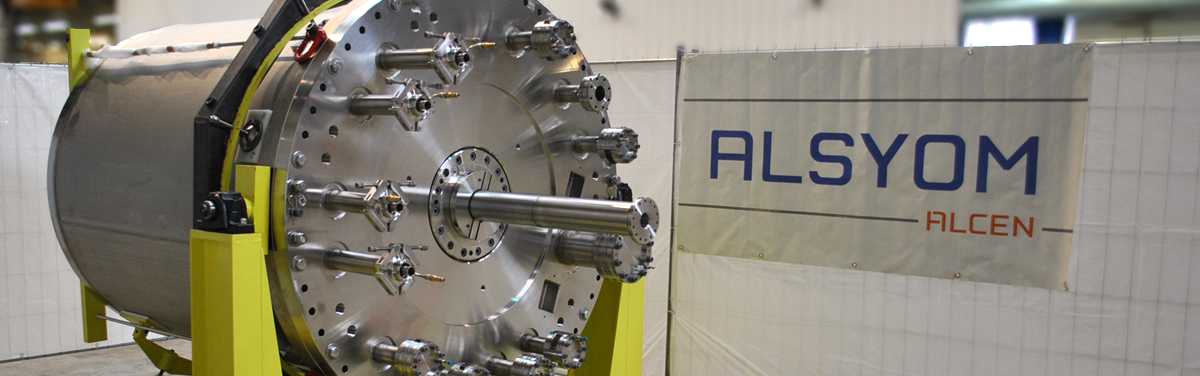

In partnership with RI-Research Instruments from Germany, ALSYMEX has been awarded a contract to manufacture the pre-production cryogenic pump by F4E.

The ALSYMEX part of the contract consists in:

- Manufacturing and assembling the Pump Plug and associated flanges, including dimensional and leak tests

- Manufacturing the Housing Sub-Assembly, including dimensional and leak tests

- Manufacturing and testing the valve shaft, head and stem assembly

The assembly of all these parts was successfully completed at the end of January on the ALSYMEX premises in Tarbes in the presence of ITER Organization, F4E and RI-Research Instruments representatives.

The pre-production cryo-pump is now being shipped to Germany where it will be fitted with all its cryogenic circuits prior to final tests.

More information on https://www.iter.org/newsline/-/2631

Main pump specifications

- Dimensions: 3.5 m long – 1.8 m diameter

- Weight: 8 tonnes

- Ultimate operating pressure: 10-7 Pa

- Charcoal cooling: 0.4 MPa pressure, 4.3K inlet temperature, 4.8K outlet temperature

- Shield cooling: 1.8 MPa pressure, 80 K inlet temperature, 90 K outlet temperature

- Actuator variable stroke up to 470 mm