Fusion is achieved when the hydrogen isotope plasma inside the reactor meets three conditions: sufficient particle density, very high temperature (in the range of 150 million °C) and sufficient confinement time.

The reactor stainless steel vacuum vessel and the powerful superconducting magnets allowing for plasma confinement must be protected from heat and neutrons generated during the fusion reaction. This is the role of the blanket that covers the inner wall of the vessel.

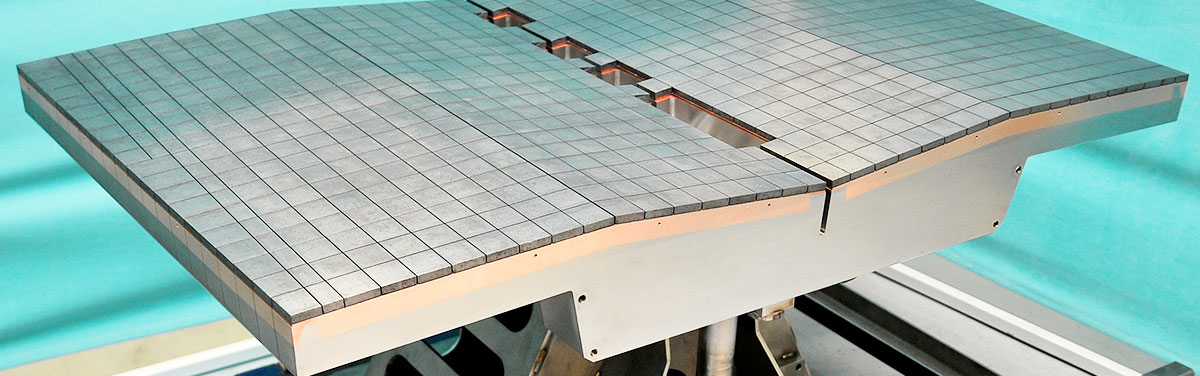

In ITER, this blanket consists of 440 panels made out of beryllium tiles joined to a copper alloy layer and a stainless steel shield block. Each panel measures 1 × 1.5 m and weighs up to 1.5 t. Roughly half of these panels are under European responsibility.

For approximately 20 years, ATMOSTAT has been developing the proper processes allowing for manufacturing and assembly of the ITER blanket panels. Making use of the company’s historical know-how in beryllium machining and in the Hot Isostatic Pressing (HIP) assembly technology, such work has been performed in particular through collaborations with the French Atomic Energy Agency (CEA) and several prototype contracts awarded by Fusion for Energy (F4E), the Barcelona-based agency in charge of the European in-kind contribution to ITER. ALSYOM, ATMOSTAT’s sister company specialized in high precision machining of large metallic components, has also been involved in these developments.

In December 2020, these technical, technological and industrial efforts have been successfully materialized by the signature with F4E of a framework contract for the series production of half of the European blanket panels.

They will mainly be manufactured in our Tarbes facility where very important investments will be made, within the next two years, to transform existing workshops into a dedicated production area equipped with all necessary machining, assembly, cleaning and testing tooling. In parallel, the required production processes will be developed and qualified through the manufacturing of three pre-series panels. A first batch of 27 series panels will then be produced by the end of 2024.

Following other on-going ITER related programs, this contract, ensuring a high level of activity within the next 7 years, will allow to further demonstrate and strengthen ALSYOM and ATMOSTAT’s capability to manage long-term complex programs as well as our organizational, technical and industrial skills to manufacture and deliver highly demanding components. More generally, it validates our strategy of being a long-term trustful partner of the ITER program.

Additional information on: