Very high-energy heating systems are required to bring the ITER plasma to the extremely high temperatures needed for the fusion reaction. In one of these systems, the Neutral Beam Injector (NBI), negatively charged deuterium ions are first accelerated to an energy in the range of 1 MeV, before going through a cell containing gas where they are neutralized. The uncharged particles are then injected into the ITER vacuum vessel where they transfer their energy, through collisions, to the plasma particles.

As the ITER NBI system is far above state of the art, its development will be achieved through intermediate steps, thereby enabling validation of the various sub-assemblies. A dedicated facility, the Megavolt ITER Injector and Concept Advancement (MITICA), has been set up in Padua (Italy), with financial contribution from Fusion for Energy (F4E), the Japanese Domestic Agency and Consorzio RFX, to perform the necessary tests.

The beam source, consisting of an RF ion source on the rear side and an electrostatic accelerator on the front side, enabling the deuterium ions to be brought up to the required energy, is one of the most critical parts of the NBI. After manufacture of an initial beam source prototype, F4E has signed framework contracts with three different suppliers, including ALSYMEX, covering three main tasks as follows:

- Design revision of the MITICA beam source

- Supply of the MITICA beam source

- Supply of the ITER beam sources

After completion of the first phase, intended to last for nine months, competition will be opened to the three suppliers for the two manufacturing phases.

Following other contracts awarded for various ITER sub-systems, such as first wall panel prototypes, the pre-production cryo-pump and the PF coil handling and assembly tooling, this award demonstrates F4E's confidence in ALSYMEX's expertise and its capability to manage a challenging multi-technology program.

The MITICA Beam Source

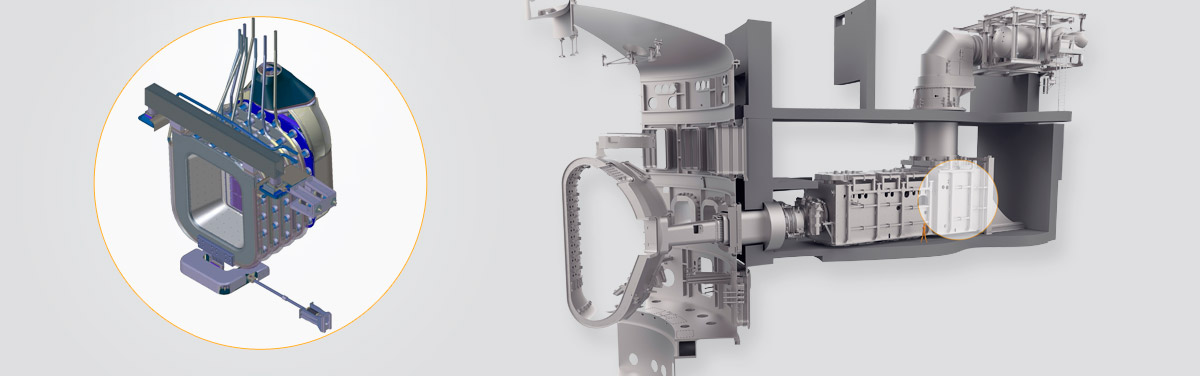

This consists of eight different sub-assemblies: an electrostatic shield, an ion source support structure, an RF ion source, an extractor, an accelerator, a set of top connections, a support and adjustment system and a tilting system. Once generated inside the RF ion source, deuterium negative ions are extracted and accelerated up to 1 MeV by the electric field generated by a system of grids at different potentials. The required acceleration current and voltages are respectively 40 A and between 200 and 1000 kV. The gap between the very accurately machined copper grids, separated by HV insulators, ranges between 70 mm and 100 mm. The assembled beam source, operating at a maximum pressure of 0.3 Pa, with a maximum “beam on” duration of one hour will be 2.8 m long, 2.8 m wide and 3.5 m high with a weight of 15 tons.

The scope of the contract

Based on the draft technical specification (including 3D CAD models, 2D drawings and associated applicable documents) for the MITICA beam source provided by F4E and RFX, the first stage of the framework contract is aimed at studying the manufacturability, assembly and testing of the source. Design revision of the beam source’s technical specification, as well as the manufacturing, assembling and testing plans will be provided and a detailed manufacturing project schedule will be developed.